Mainstream Engineering Awarded Contract from the US Army for a Battery Analyzer

ROCKLEDGE, FL — July 21st, 2017 — Mainstream Engineering Corporation, a 31-year-old Brevard County manufacturer with a history of leading-edge research and development that has resulted in advanced, lean-manufacturing, cost-competitive products, which are all Made in the USA, has been awarded a contract from the U.S Army for Predictive Models of Lead Acid Battery State of Charge and Health.

Absorbed Glass Mat (AGM) and flooded lead-acid batteries are widely used on 95% of military ground vehicles for Starting, Lighting, and Ignition (SLI) and silent watch applications. Not only does the battery represent one of the top ten ongoing maintenance costs for military vehicles at ~$100M for maintenance costs per year, but they also tend to fail unexpectedly. Often the first sign of a battery issue is that the vehicle designated for a mission simply will not start. Vehicle battery degradation and failure can occur earlier than expected due both to intrinsic issues and improper maintenance. Common failure modes include loss of electrolyte, acid stratification, improper charging profiles (failure to fully charge the battery) leading to sulfation, electrode corrosion, and separator failure. Current battery testers generally measure cold-cranking amps (CCA) and voltage but do not provide information about battery capacity which is arguably the most important measurement of battery performance. Recent results using electrochemical impedance spectroscopy (EIS) have shown promise providing insight into the chemical state of the battery which is important to detect sulfation, electrode corrosion, and separator failure, however, system complexity and difficulty interpreting results have hampered implementation. The Army needs both hand-held and on-vehicle prognostic/diagnostic tools to capable of determining battery state of charge, capacity, level of acid stratification; sulfation, surface charge, and predicting imminent failure and providing possible corrective actions regardless of cause. The goals of this topic are to develop an improved understanding of methods to understand the chemical state within a lead-acid battery to detect battery degradation and failure modes and develop advanced techniques for monitoring, diagnosis, and prognosis specifically for lead-acid batteries to enable reduced battery maintenance and increased battery service life.

About Mainstream Engineering Corporation

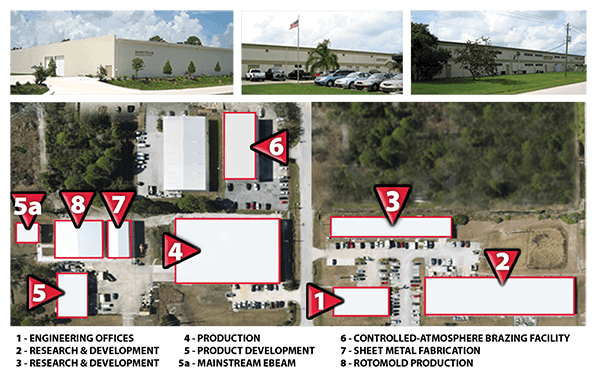

Mainstream Engineering Corporation is a solutions-oriented research, development, and manufacturing small business with a history of leading-edge R&D that has resulted in advanced, American-made, cost-competitive products. Founded in 1986, Mainstream’s mission is to transition thermal control, energy storage, and energy conversion technology into high-quality, cost-effective, environmentally safe green, commercial products. Products include lightweight diesel engines, thermal control units, biomass conversion technologies, refrigerators/freezers for shipping containers, and the QwikProduct™ line of heating, ventilation, air conditioning, and refrigeration (HVAC/R) products. Areas of research include thermal control, energy conversion, power electronics, turbomachinery, chemical technology, and materials science.

Absorbed Glass Mat (AGM) and flooded lead-acid batteries are widely used on 95% of military ground vehicles for Starting, Lighting, and Ignition (SLI) and silent watch applications. Not only does the battery represent one of the top ten ongoing maintenance costs for military vehicles at ~$100M for maintenance costs per year, but they also tend to fail unexpectedly. Often the first sign of a battery issue is that the vehicle designated for a mission simply will not start. Vehicle battery degradation and failure can occur earlier than expected due both to intrinsic issues and improper maintenance. Common failure modes include loss of electrolyte, acid stratification, improper charging profiles (failure to fully charge the battery) leading to sulfation, electrode corrosion, and separator failure. Current battery testers generally measure cold-cranking amps (CCA) and voltage but do not provide information about battery capacity which is arguably the most important measurement of battery performance. Recent results using electrochemical impedance spectroscopy (EIS) have shown promise providing insight into the chemical state of the battery which is important to detect sulfation, electrode corrosion, and separator failure, however, system complexity and difficulty interpreting results have hampered implementation. The Army needs both hand-held and on-vehicle prognostic/diagnostic tools to capable of determining battery state of charge, capacity, level of acid stratification; sulfation, surface charge, and predicting imminent failure and providing possible corrective actions regardless of cause. The goals of this topic are to develop an improved understanding of methods to understand the chemical state within a lead-acid battery to detect battery degradation and failure modes and develop advanced techniques for monitoring, diagnosis, and prognosis specifically for lead-acid batteries to enable reduced battery maintenance and increased battery service life.

About Mainstream Engineering Corporation

Mainstream Engineering Corporation is a solutions-oriented research, development, and manufacturing small business with a history of leading-edge R&D that has resulted in advanced, American-made, cost-competitive products. Founded in 1986, Mainstream’s mission is to transition thermal control, energy storage, and energy conversion technology into high-quality, cost-effective, environmentally safe green, commercial products. Products include lightweight diesel engines, thermal control units, biomass conversion technologies, refrigerators/freezers for shipping containers, and the QwikProduct™ line of heating, ventilation, air conditioning, and refrigeration (HVAC/R) products. Areas of research include thermal control, energy conversion, power electronics, turbomachinery, chemical technology, and materials science.