Mainstream Engineering Awarded Contract from the Department of Energy to Develop New Technology for Nuclear Reactors

ROCKLEDGE, FL — [July 9, 2019] — Mainstream Engineering Corporation, a 33-year-old Brevard County manufacturer with a history of leading-edge research and development that has resulted in advanced products, which are all Made in the USA, has been awarded a follow-on contract from the Department of Energy (DoE) to further develop unique metallic alloys for use in molten salt reactors (MSRs). The new technology will substantially reduce maintenance costs for the upcoming Generation IV nuclear reactors.

Mainstream first developed a metal resistant to fluoride salt corrosion with its one-of-a-kind EBEAM system. Mainstream engineers have demonstrated bonding of metal plates as a corrosion-resistant cladding on stainless steel. The next step is to refine the process for improved material uniformity and applicability to any part shape.

This new process for alloy manufacturing will reduce MSR manufacturing cost, lead time, and maintenance frequency. Conventional techniques limit the corrosion resistant cladding to simple flat or cylindrical shapes. Mainstream’s technology allows the cladding to conform to any shape, reducing corrosion on complex-shaped components.

These improved parts are intended for implementation in the next generation nuclear reactors which replace the aging US reactor fleet. Reduced corrosion will save many hours of labor, improve safety, and improve power grid reliability.

About Mainstream Engineering Corporation

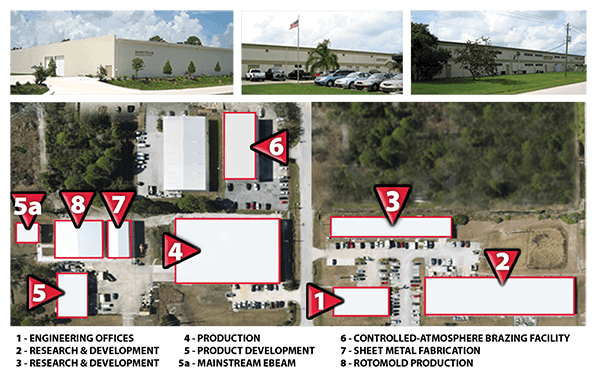

Mainstream Engineering Corporation is a solutions-oriented research, development and manufacturing small business with a history of leading-edge R&D that has resulted in advanced, American-made, cost-competitive products. Founded in 1986, Mainstream’s mission is to transition thermal control, energy storage and energy conversion technology into high-quality, cost-effective, environmentally safe, green commercial products.

Mainstream first developed a metal resistant to fluoride salt corrosion with its one-of-a-kind EBEAM system. Mainstream engineers have demonstrated bonding of metal plates as a corrosion-resistant cladding on stainless steel. The next step is to refine the process for improved material uniformity and applicability to any part shape.

This new process for alloy manufacturing will reduce MSR manufacturing cost, lead time, and maintenance frequency. Conventional techniques limit the corrosion resistant cladding to simple flat or cylindrical shapes. Mainstream’s technology allows the cladding to conform to any shape, reducing corrosion on complex-shaped components.

These improved parts are intended for implementation in the next generation nuclear reactors which replace the aging US reactor fleet. Reduced corrosion will save many hours of labor, improve safety, and improve power grid reliability.

About Mainstream Engineering Corporation

Mainstream Engineering Corporation is a solutions-oriented research, development and manufacturing small business with a history of leading-edge R&D that has resulted in advanced, American-made, cost-competitive products. Founded in 1986, Mainstream’s mission is to transition thermal control, energy storage and energy conversion technology into high-quality, cost-effective, environmentally safe, green commercial products.